Find and Finder Of The Month: David and Liron Shimron and A Small Iron Tool

David Shimron and his wife Liron traveled from Tiberias to Jerusalem to participate in the sifting alongside David’s mother and brother. They came not seeking treasure, but to share a meaningful family experience. Yet, as they sifted through the soil, an iron object unexpectedly emerged, at first glance seeming like a simple handle or a small tent peg.

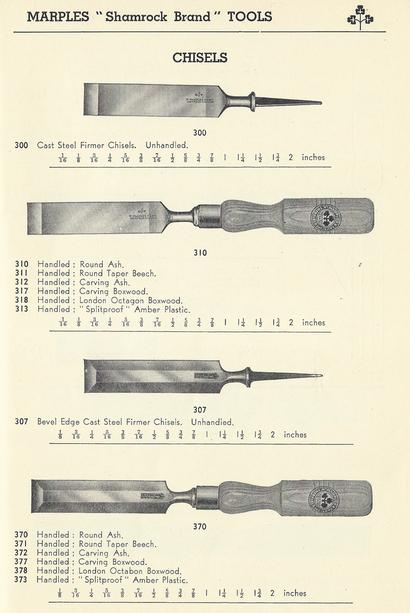

Closer inspection revealed a carefully shaped iron tool 15-16 cm long. One end flares into a broad, flat, rectangular blade roughly 5 cm long and 1.5 cm wide. The cutting edge is set at an angle (skew), while the other tapers to a pointed tang. Near the center, the metal thickened slightly to form a collar, a natural hand-stop that allows precise control.

The object is best identified as a skewed palm-chisel, also known as a scarpel from the Latin scarpellum / scalpellum, meaning a small cutting or scraping knife. Unlike heavier chisels struck with a mallet, palm-chisels are guided by the fingers and palm for delicate, shallow work. Their flat, beveled edge is ideal for shaving thin layers, skiving leather, refining surfaces, shaping joints, or creating decorative detail. Of course, this was just one tool in a craftsman’s toolkit, some tools accomplishing even more fine and precise work.

Comparable tools appear in varying regions around Europe and the Middle East and all through the archaeological record, because once artisans discovered an efficient, ergonomic form for a small scraper-chisel, there was little reason to change it. Since the design persisted over centuries, the tool’s shape alone cannot securely date the object. In the mixed soil of the Temple Mount, it could belong to any number of periods, from antiquity through the post-medieval period (though the tool’s excellently preserved state hints at a later date). What it reliably indicates, however, is the type of work it was intended to perform.

Tools like this are particularly suited for wood, bone, horn, and leather, materials requiring fine, controlled shaping. They excel at carving: shaping joints, smoothing surfaces, or adding decorative detail. It is entirely conceivable to imagine such a tool being used on ornate wooden architectural elements like those described in historical sources for the Temple, or later sacred buildings on the Mount.

Supporting that idea, Peretz Reuven, a researcher with the Temple Mount Sifting Project, has documented intricate wooden beams from the Temple Mount area that were in secondary use in the Al-Aqsa mosque and were crafted with elaborated floral designs. Even today, craftsmanship continues on the Mount: for example, wood and plaster artisans working in the gypsum‑window workshop at Al‑Aqsa are using hand tools and traditional carving techniques to restore and create windows for the mosque, showing that centuries‑old craft traditions persist.

We cannot say exactly who last used this tool, or what they were shaving, scraping, or carving on the day it was dropped or discarded. It speaks of the quiet skill of working hands, the practical intelligence of a shape refined over centuries, and the real possibility that this tool helped shape wood that once served in one of the most historically and spiritually significant places on Earth. It may have belonged to a skilled artisan, or it may have been the practical implement of a humble craftsman working in a modest workshop. Either way, it was clearly built for hands-on work with stubborn materials. Found in the sifting trays by David and Liron, this small iron mystery offers a rare glimpse into the everyday labor, whether grand or ordinary, that once took place on one of the most storied hills on earth.

Discover more from The Temple Mount Sifting Project

Subscribe to get the latest posts sent to your email.

Leave a Reply

Want to join the discussion?Feel free to contribute!